Grease is a problem in drainage operation as it does not dissolve in water. Large amounts of oil and grease in the wastewater systems, block pipes & puts excessive loads on Sewage Treatment Plants. This increases maintenance requirements for the whole system and reduces their operating life. The buildup of grease in the system also blocks sewers and floods food preparation areas. Oil and grease also affect the proper treatment of wastewater before disposal.

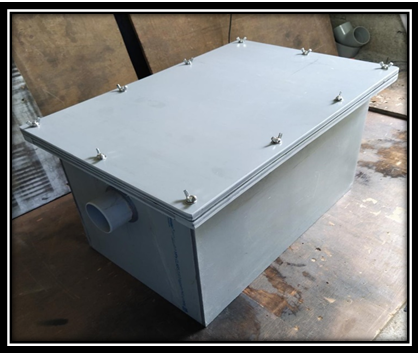

Grease Interceptors (also known as Grease Separators, Grease Traps) are a piece of equipment for all food preparation areas. These treat waste water from kitchens and food processing that contain a mixture of Water, Food and Fats, Oils & Grease (FOG). FOGs have a density less than water. Under normal operating conditions, these contaminants will naturally float on the water’s surface. Separated FOGs are retained in the grease trap by its DM approved design & the food waste is contained by the internal strainer basket, whilst cleaner ‘grey’ waste water passes through the separator via a submerged outlet to the main drain. When a significant layer of grease has accumulated, the trap must be cleaned out.

When performed properly and at the appropriate frequency, grease interceptor and trap maintenance can greatly reduce the discharge of FOGs into the wastewater system. The required maintenance frequency for grease interceptors and traps will depend on the amount of FOGs a facility discharges from its equipment.

Grease Trap mainly we supply the following Type :

• Type A 50 GPM– for small cafeterias

• Type B 100 GPM– for small restaurants

• Type C 175 GPM– For Large Restaurants

• Type D 15 GPM – for food kiosks(Under sink model)

Technical Details & Roughing-in Drawings are available on our Resources